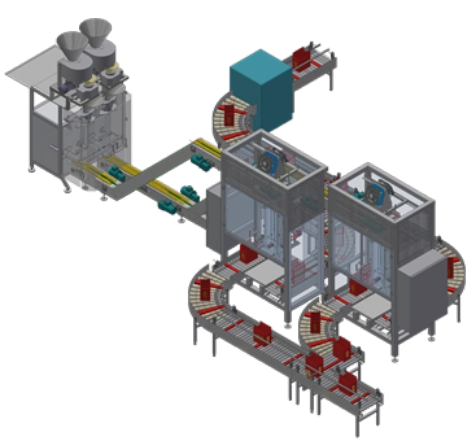

– Automatic infeed, positioning and loading of empty boxes with buffer system.

– Compact robotic cell for product pre-packing and loading.

– Transport of full crates to the closing station.

– Palletizer.

COALZA is expanding its range of solutions beyond vertical packaging machines. We are adding end-of-line automations, such as case packing and palletizing, to our portfolio of solutions. We also create process automation solutions for any stage of the production line.

CONFIGURATION OF THE PARAMETERS BY THE CONTROLLER

The configuration of the parameters, either by the controller or by adjusting the volume or weight, directly influences the accuracy of the measurement, the speed of the process, the functionality of the sensors and the activation of the corresponding alarms.

SOFTWARE AND CONTROL

When combined with a COALZA vertical packaging machine, the configuration of the dosing system is integrated into the software and the machine control

BULK PRODUCT ACCESS AT THE DOSING UNIT INLET

Clear access at the inlet of the dosing unit ensures bulk product flow, facilitating accurate and uniform dosing.

This optimizes the operation of the dispenser and its integration with conveying and storage systems, improving the efficiency of the production line.

ELEVATORS AND BELTS

We manufacture a wide variety of elevators, conveyors and transport systems adapted to the requirements of the sector, the type of product and the distribution of the bagging system in the production and packaging plant of our customers.

MEASUREMENT AND SELECTION OF THE CONFIGURED PRODUCT QUANTITY

The measurement and selection of the configured product quantity guarantees precision and adaptability in production, maximizing the efficiency and quality of the final product.

DOSAGE

– Top cone of the vertical packaging machine.

– Directly on the preformed container.

Manufacturers of high performance packaging machinery.

Packaging solutions adapted to the needs of products and production processes.

Innovation and experience, leaders in the sector.

+34 963 671 736 | +34 652 093 636 | info@coalza.com